Auftragsmessungen für Pulver & Schüttgüter

- Technologische Auslegung von Silos und Schüttgutbehältern

- Siloberechnungen und Einwirkungen auf Silos nach DIN EN 1991-4

- Auslegung von Förderanlagen (Schneckenförderer, pneumatische Förderung)

- Überprüfen der Silogängigkeit neuer Schüttgüter

- Identifizierung von Fließproblemen

- Vergleich der Fließfähigkeit von Schüttgütern

- Qualitätskontrolle und Produktzertifizierung

- Optimierung von Fließhilfsmitteln und/oder verfahrenstechnischer Prozesse

- Zeitverfestigung von Schüttgütern

- Siloauslegung für Massenfluss

- Brückenbildung vermeiden & Auslauföffnung bestimmen

- Prozesskontrolle zur Vermeidung von Betriebsstörungen und/oder Schäden

- Vermeidung von Problemen bei Produktumstellung

- ...

Rehologische Schüttgutmessungen

Nutzen Sie unsere über dreißigjährige Erfahrung in der Schüttgutanalyse. Alle Messungen werden auf standardisierten und zertifizierten Messgeräten in unserem Labor fachgerecht durchgeführt. Damit erhalten Sie reale physikalischen Stoffdaten, die zur Charakterisierung und als Grundlage für weitere technologische Berechnungen notwendig sind.

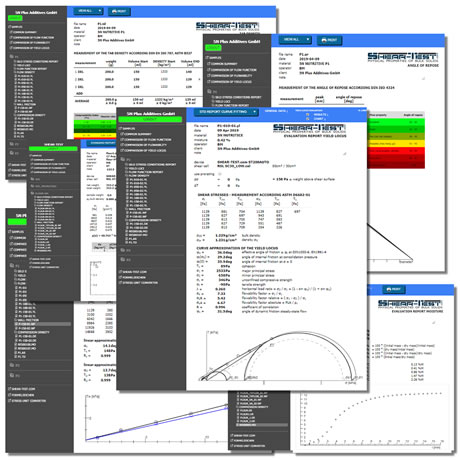

Durchgängig digitalisierte und vernetzte Prozesse – von der Probenvorbereitung über die Messung bis zur Auswertung – sichern höchste Qualität und eine zügige, kosteneffiziente Durchführung.

- Fließort

ASTM D6682-A, innerer Reibungswinkel φi, effektiver Reibungswinkel φe, Kohäsion Τc, Horizontallastverhältnis λ u. λ0 , Druckfestigkeit σc, Fließfähigkeitsfaktor (FL, FLA, FLR bzw. ffc),

+ Zeitverfestigung

- Wandreibung

ASTM D6682-B, Wandreibungswinkel φw bzw. φx, Wandreibungskoeffizient μw, Adhäsion Τw,

+ Zeitverfestigung

+ Wandoberflächenveränderung

- Schüttdichte,

Kompressionsdichte

Schüttdichte ρb0, ρSch nach EN ISO 60; USP 616, Methode III,

ASTM D6682-C Funktion der Schüttgutdichte (Kompressionsdichte) ρb(σ),

ASTM D6682-A Fließdichte ρbr(σr)

- Schüttgutfeuchte

%M (Prozent Feuchte), %S (Prozent Feststoff), ...

- Schüttwinkel, Böschungswinkel

DIN ISO 4324, ASTM D6393

Schüttgutauswertungen

Sie erhalten die Messergebnisse in klar strukturierten Tabellen und anschaulichen Grafiken, die Ihnen die Charakterisierung und weiterführende Berechnungen erleichtern. Gegenüberstellungen von Schüttguteigenschaften sowie häufig genutzte Schüttgutfunktionen werden automatisch berechnet und ergänzen die Auswertungen. Unser Berechnungstool ermöglicht es, verschiedene Silogeometrien vorzugeben und die daraus resultierenden Spannungen sowie Fließprofile im Silo zu analysieren, sodass potenzielle Probleme frühzeitig erkannt werden können. Auswertungen und Berechnungen erfolgen unter anderm nach den Vorgaben der DIN EN 1991-4 und unterstützen Sie bei der optimalen Planung Ihrer Silogeometrie.

- Rohdaten und Auswertung der einzelnen Messungen

Fließort, Wandreibung, Schüttgutdichte, Zeitverfestigung, Schüttgutfeuchte, Schüttwinkel, Klopfdichte, ...

- Deskriptive Statistik einer und/oder mehrerer Schüttgüter

- Fließortschar innere Reibung (linear und exponentiell)

- Funktion effektiver Reibungswinkel φe(σ1)

- Fließfunktion

σc(σ1), Fließfähigkeitsfaktor FL(σ1),

ffc(σ1)

- Dichtefunktion ρb(σ1),

Fließdichte

ρbr(σr)

- Einfluß der Zeitverfestigung

- Förderanlagen-Analyse

Berechnung und Bewertung verschiedener Fördersysteme (Schneckenförderer, pneumatische Förderung in Dünn- und Dichtstromphase), Blockagerisiko-Bewertung, Leistungsbedarfsberechnung, Betriebsparameteroptimierung basierend auf Materialeigenschaften (φi, Kohäsion, Dichte, Fließfähigkeit) - Siloberechnung

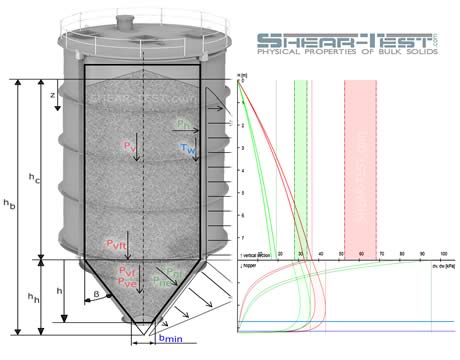

Mittelwerte inkl. Standardabweichungen SD, Streukoeffizienten aK, aμ, aγ, Siloklassifizierung nach DIN EN 1991-4, Silodruckberechnung Vertikaldruck Pv, Horizontaldruck Ph, Wanddruck Pw im Schaft und Trichter für (aktiven) Füllzustand und (passiven) Entleerungzustand, Grenzkriteriums für Massen-/Kernfluss, Belastung am Austrag, Brückenbildung im Silo (kritischer Auslaufdurchmesser), ...

Professionelle Auftragsmessungen für Pulver & Schüttgüter

Benötigen Sie präzise Charakterisierung Ihres Schüttguts? Unser Labor bietet standardkonforme Messungen für sichere Siloauslegungen.

Gerne beraten wir Sie bei der Auswahl der geeigneten Prüfungen nach Ihren Anforderungen. Nach Erhalt der Proben führen wir die vereinbarten Messungen schnellstmöglich durch und stellen Ihnen einen umfassenden Bericht mit Auswertungen zur Verfügung.

- ✓ Fachkundige Beratung

- ✓ Schnelle Durchführung der Messungen

- ✓ Umfassender Bericht mit Auswertungen

- ✓ Persönliche Betreuung und Nachbesprechung der Ergebnisse

- ✓ Empfehlungen für die praktische Umsetzung